YONGNING

NEWS CENTER

Suspended Reciprocating Grate Description

Release Time:

Dec 02,2020

Simple Introduction

Wafangdian City Yongning Grate Manufacturing Co., Ltd. was established in 1988.It covers an area of 50,000 square meters and is a professional manufacturer of boiler auxiliary machines designated by the state, located in southern Liaoning, south of Dalian, west of Bohai Bay, and east of the Shenda Expressway, with convenient transportation and a superior location.

Our factory can design and produce various grates according to user requirements to meet market needs. With strong technical strength and advanced and complete production equipment, we have laid a strong foundation for creating excellent products. For many years, we have supplied many domestic boiler manufacturers, and our products cover all parts of the country, with exports to neighboring countries such as Japan, Indonesia, and North Korea, receiving high praise.

Our main products include: beam-type chain grates, flake-type chain grates, small flake-type chain grates, various slag discharge machines, coal feeding machines, grate reducers, layered coal bunkers, various boiler accessories, and we undertake various projects for the design, transformation, installation, and maintenance of grates.

"Quality is fundamental, sincerity reaches the world." is the purpose of our factory's development. Factory director Wang Cong is willing to work hand in hand with new and old friends at home and abroad for mutual cooperation and development.

1.The hanging reciprocating grate is a new type of hanging active propulsion device developed by Yongning Grate Manufacturing Co., Ltd. This device differs from previous grates in that the hanging reciprocating grate uses multiple independent active frames to create a dynamic hanging swinging structure.

2.The working principle of the hanging reciprocating grate is to evenly arrange one or more load-bearing fixed beams on the transverse coordinates of the grate. A reasonable arrangement of an independent active frame is made between the load-bearing fixed beams or wall panels. The upper part of the fixed beam and the lower part of the active frame are welded with a hanging shaft device. The hanging shafts are connected by chain plates, and there are limit devices between the chain plates and the shafts. There are also lateral limit devices between the active frame and the load-bearing fixed beams. Under the thrust of the transmission device, the active frame can perform accurate reciprocating motion between the load-bearing fixed beams (the entire device is like a swing).

3.Scope and requirements of use:

The hanging reciprocating grate can be matched with boilers of 1-100t/h and is suitable for burning bituminous coal, lignite, and peat.

4.The medium used in this grate should meet the following requirements:

a. The maximum particle size of coal blocks must not exceed

b. The moisture content of the coal should be less than 20%, preferably 8-10%.

c. The ash content of the coal should not be less than 10%.

d.Caking property should not be strong.

The primary air temperature used in this grate must not exceed 20℃.

5. Classification of hanging reciprocating grates:

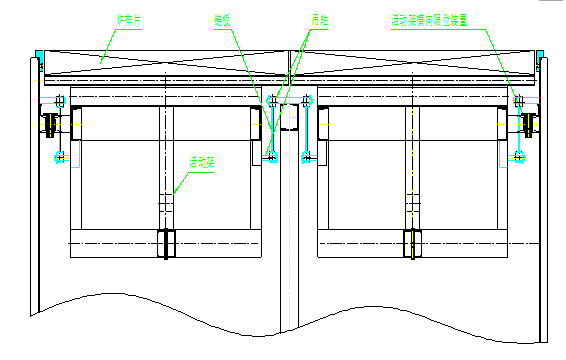

Hanging reciprocating grates are divided into horizontal hanging reciprocating grates and inclined hanging reciprocating grates. Their common structural forms are shown in the attached drawings. They can also be designed according to specific user requirements for side air entry and rear air entry. However, the specific structural forms of wall panels, air boxes, elevated structures, or low frame structures.

6.Structural characteristics of hanging reciprocating grates

The ignition and combustion of fuel on the hanging reciprocating grate, except for the head of the combustion bed, is basically double-sided ignition. Due to the continuous raking and loosening of the fuel layer, the permeability is enhanced, greatly increasing the contact between air and fuel. Moreover, the ash shell on the surface of the caking blocks and coal particles is crushed or shed due to the squeezing and flipping, which is beneficial for enhancing combustion and improving the burnout of coal particles. Therefore, the adaptability of the fuel is better than that of chain grates, especially for inferior bituminous coal that is strongly adhesive, has a high ash content, and is difficult to ignite. The ventilation cross-section of this grate is 7-12%. Its metal content is lower than that of chain grates, and the manufacturing process requirements are not high. This grate has a high degree of mechanization, a compact structure, and is convenient for use and maintenance.

This grate consists of a coal feeding hopper, supports, active beams, fixed beams, grate pieces (active grate pieces and fixed grate pieces), front wind doors, and a transmission system. The working surface of the grate is composed of active grate pieces and fixed grate pieces. The active grate pieces move back and forth on the active steel frame, allowing the fuel to be transported, burned, and the slag to be discharged on the surface of the grate. The specific characteristics are as follows:

A. The movement of the active frame is provided by the transmission system, and the fixed pieces remain relatively stationary on the fixed beams.

B. The interior of the grate uses segmented air supply. Several independent air chambers are set along the longitudinal direction of the grate, and the primary air entering the air chambers from the air boxes or ducts on both sides of the grate slows down due to diffusion and can evenly fill the air chambers. The air volume entering each air chamber can be adjusted through an air adjustment device.

C. The sealing between the sides of the grate and the supports is achieved using vertical plates or blocks to prevent air from leaking into the air chambers.

D. The coal feeding hopper is installed on the front wall panels on both sides of the supports, and the thickness of the coal layer is adjusted by the lifting of the coal gate.

E. The transmission system drives the active grate pieces to move, and the speed of movement can be adjusted according to the burnout of the ash and slag, allowing the fuel to be fully burned.

F. The ash removal from the grate can be arranged on one side or both sides of the grate, using manual ash removal to ensure timely clearance of ash and slag; the ash removal for the double-layer reciprocating grate is done at the lower part of the grate (through the ash hopper).

G. This grate has been strictly debugged on-site and is shipped as a complete unit.

Use of the suspended reciprocating grate

1.On-site inspection and adjustment of the grate

After the entire boiler is installed, a careful inspection and cold no-load test of the grate must be conducted before drying the furnace.

a. Carefully check that there are no foreign objects or defects such as burrs between the movable and fixed pieces.

b. Carefully check that there are no iron parts or other debris lost or trapped anywhere on the grate.

c. Check whether the air adjustment device is flexible and troubleshoot any faults.

d. Check whether the coal gate rises and falls flexibly, and whether the distance from both sides to the grate surface is equal.

e. The cover plate on the coal gate must be properly covered to prevent coal blocks from leaking in and jamming the coal gate, affecting its up and down movement.

f. After conducting the above inspections and adjustments, a cold operation test should be performed. If any abnormal phenomena are found, stop the machine immediately, troubleshoot, and continue until normal operation for more than 8 hours. The cold operation should meet the following requirements:

1.The temperature rise of the gearbox oil pool must not exceed 35oC, and the temperature rise of the bearings must not exceed 40oC.

2.The current and temperature rise of the motor must not exceed the rated values.

3.The grate operates smoothly, rotates flexibly, and shows no noise, deviation, arching, or jamming.

4.The deviation of the grate should not exceed the design gap between the grate pieces and the protective plate.

g.The reciprocating grate pieces should not be too tight.,Otherwise, during combustion, the grate will expand due to heat.,After the grate expands too tightly, the edge pieces of the grate will press against the side seals on both sides of the grate.,This can lead to damage to the grate pieces and the grate beam.

2.Ignition use

Place ignitable materials in front of the grate to ignite, increase the induced draft, after the ignitable materials burn, manually add coal on top of the ignitable materials, at this time turn on the blower, after the coal layer burns vigorously, add coal into the coal hopper, intermittently operate the grate, and observe the ignition situation at the observation hole, appropriately adjust the fire; wait for the front arch to heat up, and if it cannot ignite continuously, operate the grate and adjust the air volume to normalize the combustion.

3.Operation management of the grate

a.The normal combustion condition on the grate is: the fire bed is flat, the flame is dense and uniform, bright yellow, with no cold air entering the fire mouth, the burnout section is neat and consistent (approximately at the end of the last fixed piece

b.It is strictly forbidden to introduce iron or other debris into the furnace to prevent jamming the grate.

c.The coal layer should maintain a certain thickness, and only when the type of coal changes or the boiler load varies significantly should the thickness of the coal layer be changed. The thickness of the coal layer is generally 80

d.The coal hopper should not be lacking in coal, and the phenomenon of "coal bridging" in the coal hopper should be eliminated at any time.

e.When coal enters the furnace, it should ignite at a distance of 200-300 from the coal gate and should not burn under the coal gate; otherwise, it will damage the coal gate. If such a situation occurs, water can be added to the coal or the speed of the grate can be increased.

f. When coal enters the furnace, if it has not ignited at a distance of 200-300 from the coal gate, it is called "loss of fire." At this time, open the furnace door to adjust the fire, that is, push the burning coal to the coal layer near the coal gate, or add flammable materials to speed up the ignition.

g.A large area of coking on both sides of the furnace and inside the furnace,the coking blocks should be cleared immediately.

h.The ash and the ash clearing area in front of the grate must be cleaned 3-4 times per shift.

i.It is strictly forbidden to burn under positive pressure; at this time, check the operation of the blower and induced draft, as well as whether the rear flue is blocked, and troubleshoot.

j."Damp furnace pressure fire" should be avoided as much as possible to prevent the grate pieces from burning out. During short-term pressure fire, the coal layer should be moved away from the coal gate

k., to prevent damage to the coal gate.

l.The shutdown of the grate is generally carried out in the following order.

m.1)

1) Stop supplying coal half an hour in advance.

2) Properly reduce the induced draft fan to let the residual coal on the grate burn out before shutting down the furnace.

3) After burning out, stop the induced draft.

4) If necessary, the grate continues to operate, and all the ash on the grate should be unloaded.

n.Emergency shutdown of the grate should be carried out in the following order.

1) .First stop the blower, then stop the induced draft fan.

2) .Run the grate at the fastest speed to send all the ash and coal out of the furnace.

3) .Shutdown.

O.The following faults may occur during the operation of the grate.

l The movable piece is not moving parallel, which may be due to loose screws on the movable beam or fixed beam.

l The movable piece is stuck at the side sealing block, which may be due to a small gap, and the gap of the grate piece can be adjusted by adjusting the piece.

l The push-pull rod and fixed sliding sleeve movement is obstructed, which may be due to lack of oil or foreign objects intervening.

l Coke blocks are too large, increasing resistance, and should be deslagged in time.

4.Maintenance and repair of the grate.

1).Regularly add lubricant to the oil cup or oil nozzle in the grate drive system, and oil twice per shift.

2) If deformation, fracture, and other phenomena are found in grate pieces, beams, etc., they should be replaced in time.

3) When the grate is disassembled for major repairs, special attention should be paid to the wear of fixed beams, movable beams, movable frames, transmission devices, etc., and serious ones should be replaced.

4) After the eccentric wheel and pull rod of the transmission system are worn, if the gap between the shaft and the hole is too large, the parts should be replaced in time to avoid affecting the operation of the grate.

5) If the furnace is shut down for a long time, the coal in the coal bunker and the collected ash in each air chamber should be cleared. Anti-corrosion agents should be added to all rotating friction parts of the grate.

RELATED INFORMATION

How to choose a Manufacturer for grate production

Apr 01,2024

Precautions for Using the Grate

Mar 07,2024

The difference between reciprocating chain grate and biomass reciprocating grate.

Feb 15,2024

Photo News