YONGNING

NEWS CENTER

Analyze the reasons for the burning loss of the chain grate.

Release Time:

May 17,2021

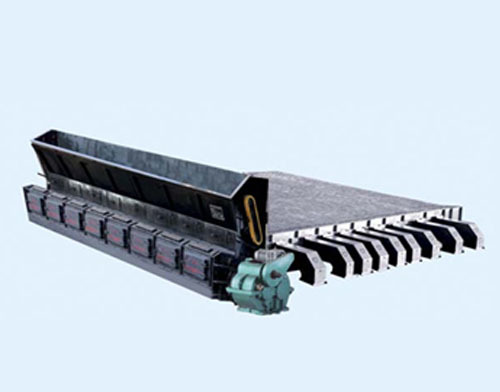

AnalyzeChain grateWhat are the causes of burning damage?

Chain grates are generally made of heat-resistant cast iron. The so-called heat resistance means that the melting point does not exceed 1200 degrees; it just has a higher red hardness temperature. In fact, since the chain grate operates in a layered combustion mode, the surface temperature of the grate is not high due to the air supply. The furnace chamber temperature is very high, but the contact temperature of the grate does not exceed 800 degrees. If it exceeds this temperature, the grate will be burned out, indicating that there is a problem with our operation. Firstly, the coal layer is too thick, causing slow movement of the grate, combined with stopping or insufficient air supply, leading to excessive surface temperature of the grate. Secondly, intermittent operation can burn the grate, whether it is a reciprocating grate or a chain grate, and the burning of the grate is caused by improper operation in certain steps.

In addition, the furnace chamber temperature of the chain grate is not significantly related to the temperature resistance of the grate. If it is normal operation, even if the furnace chamber temperature is high, it will not burn out the grate. Moreover, there are currently no grates that can withstand such high temperatures. Even stainless steel has a melting point of 1700 degrees. Let's analyze the causes of grate burning together.

Chain grateCauses of burning damage

1. The coal layer on the grate is uneven, the temperature is too high, and unburned coal accumulates at the eagle iron and continues to burn.

2. Due to the lack of regular ash removal from the shielding plate in the lower part of the grate, the coal dust and small coal pieces leaking from the fire chamber continue to burn in the small ash hopper, causing the grate to bend and deform, and eventually break the grate chain.

3. When buried in fire, the lower part of the grate loses cooling, burning out the grate bars and chains.

Methods for handling chain grates

1. Carry out modification operations to level the coal pile.

2. Regularly remove ash.

3. Improve the push-fire operation technique.

Chain grateCauses of jamming

1. The movable gap is too small.

2. The stroke is too large, causing the moving grate piece and the fixed grate piece to lead to death.

3. Jammed on the grate, not moving.

4. Iron parts jammed in the gaps.

5. The push-pull shaft and eccentric rod are not in the same line.

Methods for handling chain grates

1. Adjust the gap to make it appropriate.

2. Control the stroke of the movable grate.

3. Straighten the movable beam.

4. Clean up the clutter.

5. Adjust the push-pull shaft and eccentric rod to ensure they are in a straight line at the dead point.

PreventionChain grateMethods of combustion

Based on the causes of occurrence, take corresponding measures. When using combustible (coke) coal or high-quality coking coal, inferior coal can be mixed for combustion. In addition, pay attention to timely stirring of the furnace slag, install silicon or silicon heat-resistant materials in the high-temperature area, increase ventilation, correct the internal reflection arch, improve the material of the grate, or use heat-resistant cast iron grates.

The above is the content shared with everyone. I hope that through the above content, you can have a better understanding and recognition of grate products. I wish everyone a happy life!

RELATED INFORMATION

How to choose a Manufacturer for grate production

Apr 01,2024

Precautions for Using the Grate

Mar 07,2024

The difference between reciprocating chain grate and biomass reciprocating grate.

Feb 15,2024

Photo News