YONGNING

NEWS CENTER

Share some common issues with chain grate stoves.

Release Time:

May 20,2021

Distribute to everyoneChain grateCommon problems that occur

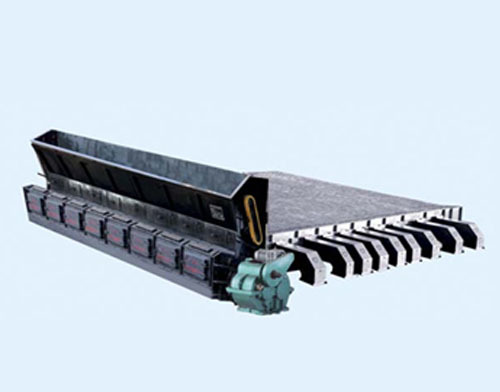

Chain grates are mechanized combustion equipment commonly used in organic heat carrier furnaces, with advantages such as reasonable structure, reliable performance, and convenient installation. However, failures may also occur during operation, so it is necessary to understand the causes of common failures of chain grates.

Chain grate expansion

The main reason is that the grate chain is loose, and combined with the thermal expansion of the grate, it can cause failures such as jamming and dropping of the grate. At this time, adjust the fastening bolts on both sides, tighten the chain, and adjust the looseness of the chain using the following method: when the grate is running in a cold state, suddenly set the speed of the reducer to zero, indicating that the grate chain instantaneously reverses, causing the grate chain to loosen. When stopping suddenly, adjust until the grate no longer reverses. In this case, after the grate expands due to heat, the looseness is appropriate.

Chain grateDeviation

The installation quality of the chain grate is unqualified, the front and rear shafts are not parallel, or the axle is bent beyond tolerance; the fastening degree of the grate adjustment nut varies greatly, causing the grate to tilt towards the rotating side, resulting in severe edge friction and refusal to move, thus causing the grate to snake. In this case, first, turn the guardrail upside down, mark the adjustment nut, loosen the adjustment nut, and symmetrically tighten after forward rotation; if the above treatment does not work, check whether the main and secondary machine shafts are bent, and replace them after correction according to the situation; after installing the main and driven shafts of the grate, measure their parallelism, levelness, and diagonal deviation. The diagonal deviation should be less than 10 mm, and the expansion gap between the large superstructure and the wallboard should be 10-12 mm. After correction, the bending degree of the large shaft should not exceed 0.5 mm. This deviation should be distinguished from the deviation after the main guiding piece of the grate is damaged. After the active piece breaks, the deflection tilts towards the undamaged side, and the tighter the adjustment nut is tightened, the more severe the deflection.

Problems related to combustion of chain grates

The combustion on the chain speed is continuous. When the load is constant, the combustion process does not change with time, eliminating the periodic influence of hand-fired furnace combustion. The chain grate is a typical pre-feeding furnace. Depending on the position of the fuel layer on the grate, the combustion conditions also differ. In other words, combustion occurs by area: new coal is preheated and dried at the front of the grate, quickly becoming the volatile release zone; the middle of the grate has a coke combustion zone; the rear is the ash settling combustion zone. The combustion of the chain grate occurs from top to bottom, and due to "single-side ignition," the ignition conditions are poor, and the adaptability of the coal type is low.

In summary, it is essential to promptly identify and resolve failure issues occurring on the grate during operation, but to ensureChain gratework efficiency, it is necessary to focus on preventing failures, improving the operational level of combustion technology, maintaining equipment, and conducting regular repairs to ensure better operation of the grate.

RELATED INFORMATION

How to choose a Manufacturer for grate production

Apr 01,2024

Precautions for Using the Grate

Mar 07,2024

The difference between reciprocating chain grate and biomass reciprocating grate.

Feb 15,2024

Photo News