YONGING

PRODUCTS CENTER

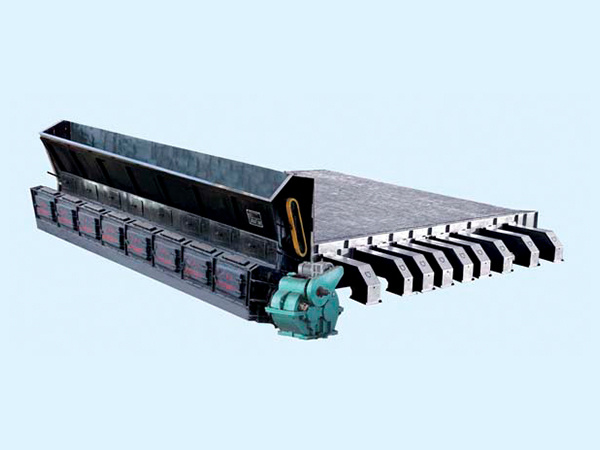

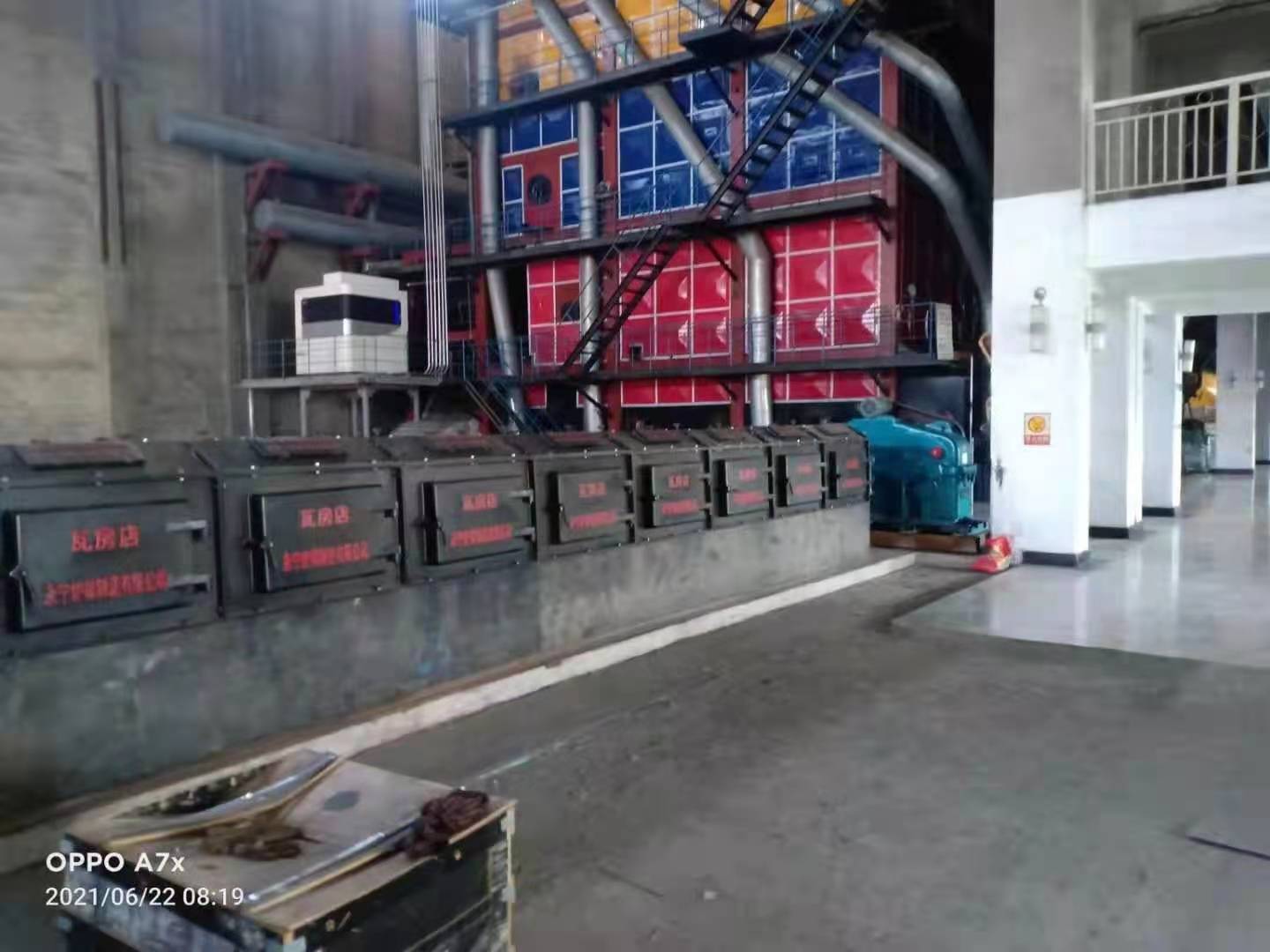

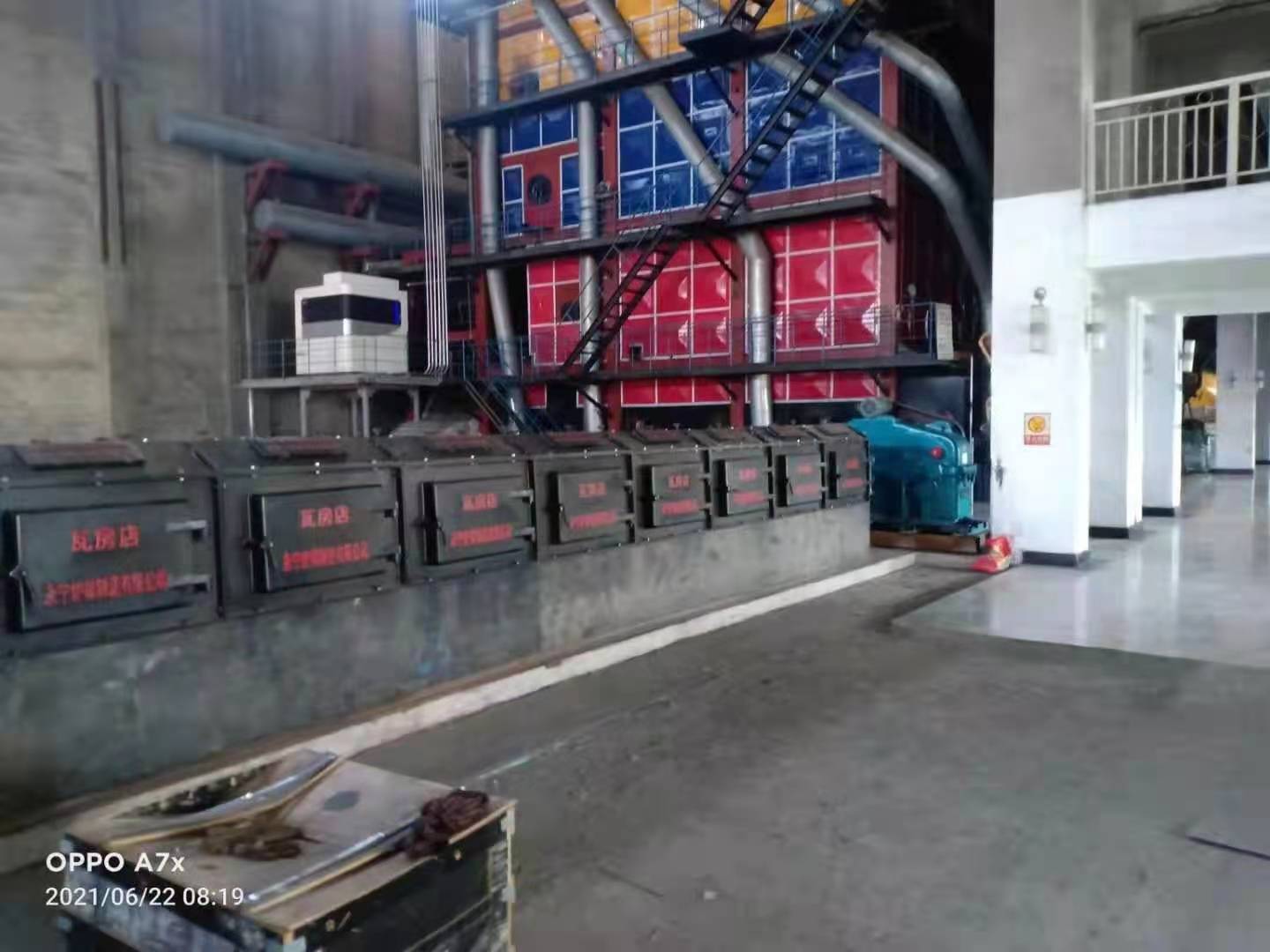

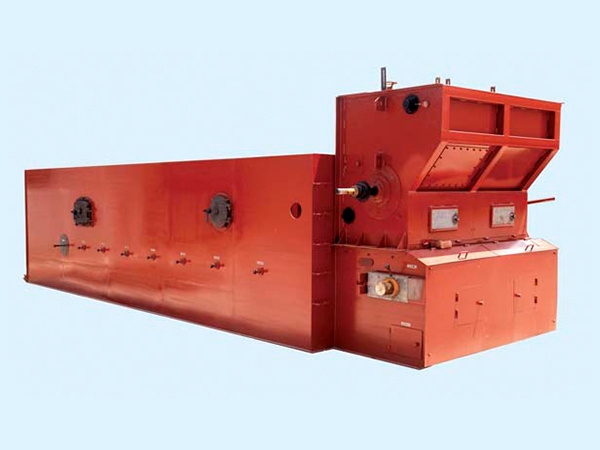

Biomass Chain Grate Stoker

Key words:

Classification:

Description

Biomass Boiler Emission Standards:

NOx < 50mg/m control methods and low nitrogen emission technologies for biomass boilers. Research has been conducted by relevant departments on the hazards of NOx, the generation mechanism of NOx during coal-fired power generation combustion, and technologies to reduce NOx. Reducing NOx is an inevitable requirement for improving air quality.

NOx control methods can be divided into pre-combustion treatment, in-combustion treatment, and post-combustion treatment. Pre-combustion denitrification refers to converting fuel into low-nitrogen fuel, which is technically complex, difficult, and costly, thus currently in the research stage; in-combustion denitrification mainly includes: first, the formation of NOx during combustion, and second, the reduction of already formed NOx; post-combustion denitrification mainly refers to flue gas denitrification: including selective catalytic reduction, selective non-catalytic reduction, etc.

John Energy-saving Boiler Structure Diagram, the high-temperature gasification boiler uses sealed feeding technology + (water-cooled grate + reciprocating grate technology) + adiabatic combustion technology + NOx high-temperature reduction technology to solve the NOx emission problem.

1. By adopting the above technologies, the original NOx emissions can generally be controlled within 200mg/m3, and using urea water reduction can directly achieve below 50mg/m3.

2. Key to controlling NOx emissions: first, control the synthesis of NOx, and second, control the reduction of already formed NOx to N2. Controlling the synthesis amount mainly involves controlling the excess air in the combustion chamber; lower excess air results in less NOx formation.

3. Sealed feeding technology, water-cooled grate + reciprocating grate are all aimed at controlling the excess air in the combustion chamber and reducing the damage of high-temperature air to the grate, with the hope of achieving a lower maintenance rate.

4. Regarding NOx high-temperature air reduction technology: since the main component of NOx in flue gas is NO, and N2 decomposes into NO at 650℃, the main work of denitrification is to remove NO. NO reacts with reducing gases such as CO, H2, CH4 at temperatures above 850℃ to be reduced to N2.

High-temperature gasification biomass boiler utilizes high-temperature air combustion technology and adiabatic combustion technology to increase the flue gas temperature. We set up a carbon monoxide generation zone in the combustion chamber, using CO to react with NO, reducing NO to N2, aiming to curb the generation of nitrogen oxides. John Energy-saving biomass boiler meets the requirements for low carbon and environmental protection.

Product Inquiry

You Can Leave Your Comments And Suggestions Here, And We Will Reply In Time.

Related Products

Beam Type Chain Grate

-

Beam Type Chain Grate

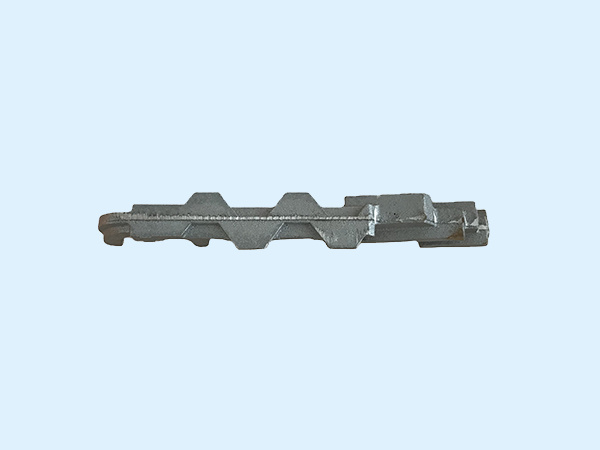

Crossbeams of high rigidness are fixed onto the chain and fire grate flakes are assembled into grooves. The advantages include: the structure is rigid; fire grates are not affected by the stress; crossbeams and chains are not affected by heat; the area of fire grate is larger; the rate of coal leakage and air leakage is lower. This technique is usually employed on 20t/h or above boilers.

-

Beam Type Chain Grate

The beam grate is a new type of beam grate plate with oblique air outlet applied to the beam-type grate. This grate plate differs from the existing grate plates in that its air outlet direction is not vertical but at an angle to the vertical direction. This allows for a horizontal component of airflow speed when the air ventilates away from the grate plate, which is beneficial for the horizontal diffusion of air in the coal layer, improving the mixing effect of coal and air, and also reducing the amount of coal leakage from the grate.

-

Beam Grate Chain Grate Stoker

The beam grate is a new type of beam grate plate with oblique air outlet applied to the beam-type grate. This grate plate differs from the existing grate plates in that its air outlet direction is not vertical but at an angle to the vertical direction. This allows for a horizontal component of airflow speed when the air ventilates away from the grate plate, which is beneficial for the horizontal diffusion of air in the coal layer, improving the mixing effect of coal and air, and also reducing the amount of coal leakage from the grate.

-

Beam Grate

The beam grate is a new type of beam grate plate with oblique air outlet applied to the beam-type grate. This grate plate differs from the existing grate plates in that its air outlet direction is not vertical but at an angle to the vertical direction. This allows for a horizontal component of airflow speed when the air ventilates away from the grate plate, which is beneficial for the horizontal diffusion of air in the coal layer, improving the mixing effect of coal and air, and also reducing the amount of coal leakage from the grate.

-

Beam Type Chain Grate

The beam grate is a new type of beam grate plate with oblique air outlet applied to the beam-type grate. This grate plate differs from the existing grate plates in that its air outlet direction is not vertical but at an angle to the vertical direction. This allows for a horizontal component of airflow speed when the air ventilates away from the grate plate, which is beneficial for the horizontal diffusion of air in the coal layer, improving the mixing effect of coal and air, and also reducing the amount of coal leakage from the grate.

-

Beam Grate Chain Grate Stoker

The beam grate is a new type of beam grate plate with oblique air outlet applied to the beam-type grate. This grate plate differs from the existing grate plates in that its air outlet direction is not vertical but at an angle to the vertical direction. This allows for a horizontal component of airflow speed when the air ventilates away from the grate plate, which is beneficial for the horizontal diffusion of air in the coal layer, improving the mixing effect of coal and air, and also reducing the amount of coal leakage from the grate.

-

Beam Grate Chain Grate Stoker Manufacturers

The beam-type chain grate is a mechanized, intricately structured staged combustion device. It can be widely used as a combustion device in large staged combustion boilers (suitable for chain grate boilers with an evaporation capacity of 20~90t/h) and various heating and drying specialized equipment. It is suitable for burning bituminous coal, lignite, and peat. With special design, it can also be used as a combustion device using fuel such as bagasse, firewood, and rice husks.

-

120-ton Beam Grate Chain Grate Stoker

-

Manufacturers of Beam Grate Chain Grate Stokers

-

Beam Grate Chain Grate Stoker Suppliers

-

Chain Grate Stoker Manufacturers

Beam Grate

-

Beam grate manufacturer

Beam Grate

-

Beam Grate Chain Grate Stoker

Yongning grate, beam grate

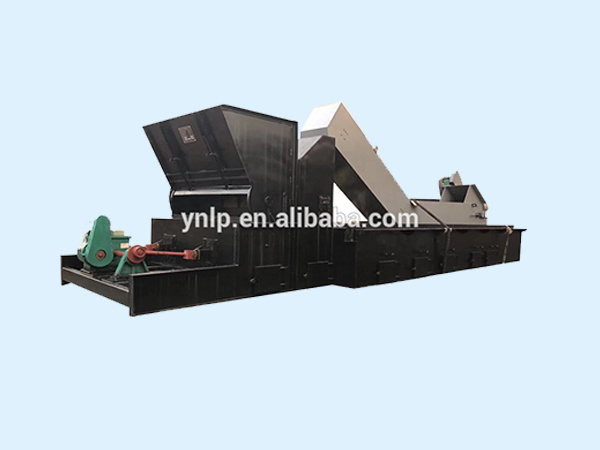

Biomass Reciprocating Grate Stoker

-

Biomass Reciprocating Grate Stoker

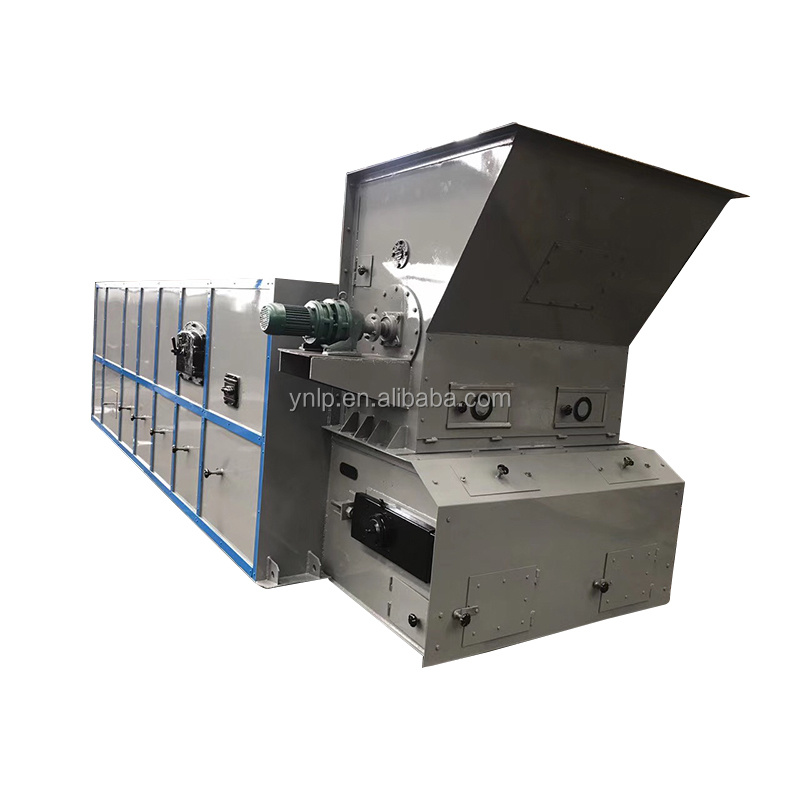

The chain grate is the most commonly used mechanized combustion equipment in organic heat carrier furnaces. It has advantages such as reasonable structure, reliable performance, and easy installation. With the application of organic heat carrier furnaces in many industrial fields, our factory has developed a series of chain grate products that match the organic heat carrier furnace series. This series uses lightweight chain belt grates and reasonable air supply devices, and strengthens the sealing on both sides of the grate, along with reasonably configured front and rear arches. It has strong combustion adaptability, reasonable combustion air supply, and quick ignition start. Operational practice has proven that it can burn coal with a calorific value of around 18840 kJ/kg, and smokeless coal and mixed coal with a volatile content greater than 20% can burn normally. Additionally, it can also burn industrial waste such as wood blocks and sugarcane residue.

-

Reciprocating Grate for Biomass

The chain grate stoker is a mechanized coal-burning device that has a long history, reliable structure, and stable operation in industrial boilers, and it has been widely used. The chain grate stoker has the following three structural forms: 1. Beam-type stoker. The beam-type stoker is suitable for boilers with an evaporation capacity of 20~40t/h or even larger.

-

Manufacturer of Biomass Reciprocating Grates

The biomass chain grate boiler mainly consists of upper and lower drums, convection tube bundles, water-cooled wall tubes, descending pipes, and a collection box. The upper and lower drums are arranged vertically, and the combustion equipment uses a chain grate driven by a continuously variable transmission. The boiler body is composed of vertically arranged upper and lower drums and convection tube bundles.

-

Biomass Reciprocating Grate Stoker Supplier

The biomass reciprocating grate device is mainly aimed at direct-fired boilers with a reciprocating grate structure, integrating the traditional multi-zone reciprocating grate into a unified reciprocating mechanism. Additionally, a meshing fixed structure is used between adjacent grate pieces on the same layer to ensure stable and safe operation of the boiler.

Biomass Chain Grate Stoker

-

Biomass Chain Grate Stoker

-

Chain Belt Grate for Biomass

-

Biomass chain grate furnace

-

Biomass Chain Grate Stoker

-

Chain Belt Grate Supplier for Biomass

-

Biomass Chain Grate Manufacturer

-

OEM/ODM biomass chain grate stoker supplier

-

Biomass Chain Grate Stoker

-

Chain Belt Grate for Biomass

-

Biomass Chain Grate Manufacturer

-

Manufacturer of Biomass Chain Grate Stokers

-

Chain Belt Grate Supplier for Biomass

-

Biomass Chain Grate Stoker

-

Biomass Chain Grate Stoker

-

High-Temperature Resistant Biomass Chain Grate

The biomass chain grate furnace uses a beam-type grate, which has low operating resistance; the cooling effect of the grate bars is good, resulting in a low failure rate; the amount of "fuel" leakage from the grate is small; it adopts a fully welded membrane water-cooled wall structure, which has good sealing and low heat loss; the design of a large cross-section and high furnace chamber, combined with secondary air and optimized arch, effectively promotes the combustion of fly ash and slag, with measured thermal efficiency approaching 90%;

-

10-ton Biomass Chain Grate Stoker

-

Biomass Chain Grate Stoker

-

Chain Belt Grate for Biomass

Yongning Grate

Reciprocating Chain Grate

-

Reciprocating Chain Grate

The reciprocating grate is an advanced combustion device, whose core working principle is to feed fuel into the furnace for combustion through the reciprocating motion of the grate. The speed, amplitude, and frequency of the grate's movement can be adjusted according to the type of fuel and combustion requirements to achieve optimal combustion results.

-

165-ton Reciprocating Grate

-

165-ton Reciprocating Grate

-

Reciprocating grate

-

Reciprocating chain grate manufacturers

-

Reciprocating chain grate suppliers

-

Manufacturers of reciprocating chain grates

-

Reciprocating Chain grate

-

Reciprocating chain grate manufacturers

The main feature of a reciprocating grate boiler is that there is relative movement between the grate and the coal. Moreover, when the moving grate is pushed backward and downward, it causes some new coal to move, which facilitates the combustion process and makes the coal layer loose and even. Therefore, based on this, the height of this boiler is somewhat higher than that of ordinary boilers.

-

Reciprocating chain grate suppliers

The reciprocating grate is a type of small mechanized grate developed based on fixed step grates. It has characteristics such as simple structure, easy manufacturing, low metal consumption, and good smoke and dust removal effects, making it widely used in small industrial boilers. There are many structural forms of reciprocating grates, with the inclined reciprocating grate and horizontal reciprocating grate being the most commonly used.

-

Manufacturers of reciprocating chain grates

-

Reciprocating grate

-

165-ton reciprocating grate

Reciprocating grate: Mostly large capacity, high parameter boilers, combustion in the fire chamber, high thermal efficiency, and the outlet working medium is superheated steam. Reciprocating grate: The reciprocating grate is used for industrial production and heating, mostly low pressure, low temperature, small capacity boilers, with combustion mainly on the fire bed, and lower thermal efficiency; the outlet working medium referred to as steam industrial boilers, and the outlet working medium referred to as hot water boilers.

-

100-ton reciprocating grate

-

Reciprocating grate

Reciprocating grate

-

Reciprocating chain grate manufacturers

Reciprocating grate

-

Reciprocating chain grate suppliers

Large Scale Chain Grate Stoker

Small scale chain grates

-

Small Flake Type Chain Grate

-

Small-scale chain grate stoker

-

Small-scale Chain Grate Stoker Manufacturer

-

Small Flake Type Chain Grate

-

Small scale chain grate

-

Small-scale chain grate stoker

-

Small-scale Chain Grate Stoker Manufacturer

The use of slotted grate has a history of several decades in our country. Based on past experience, slotted grates are well-received by users due to their simple and reliable structure. Therefore, in recent years, they have been widely used not only in large chain boilers but also in medium and small boilers of 6 tons/hour and 10 tons/hour. With the increase in grate size, and due to some components currently having manufacturing issues, the reliability of grate operation has decreased, which undoubtedly greatly affects the energy-saving efforts of industrial enterprises.

-

Small-Segment Traveling Grate Manufacturer

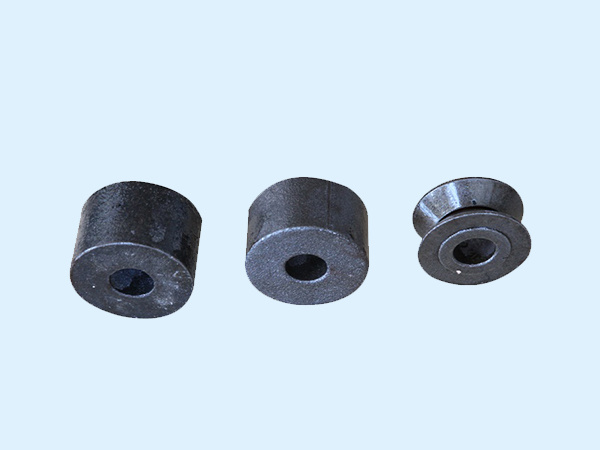

The scale grate is suitable for boilers with an evaporation capacity of 10 to 60 tons per hour. Its scale grate surface is usually composed of 4 to 12 parallel chains (similar to the chain structure on a bicycle). Each chain is connected by several components such as large rings, small rings, washers, and liners using a clevis pin. The scale grate plates are assembled on the chains with clamping plates, overlapping in the front and back, closely fitting together, resembling fish scales.

-

Wear-resistant grate accessories

The main products produced by Yongning Grate include 10-160 tons of equal pressure air supply beam-type grates; 10-65 tons of equal pressure air supply large scale chain grates; 2-40 tons of equal pressure air supply small scale chain grates; 1-20 tons of equal pressure air supply lightweight chain belt grates; 1-120 tons of suspended equal pressure air supply reciprocating grates; and layered combustion coal bunker and other grate accessory products. Yongning Grate mainly deals in coal feeders, slag dischargers, layered coal bunkers, reciprocating grates, beam grates, grates, grate accessories, biomass chain grates, chain grates, boiler grate accessories, boiler accessories, and scale grates.

-

Small-Segment Chain Grate Supplier

The main products produced by Yongning Grate include 10-160 tons of equal pressure air supply beam grates; 10-65 tons of equal pressure air supply large scale chain grates; 2-40 tons of equal pressure air supply small scale chain grates; 1-20 tons of equal pressure air supply lightweight chain belt grates; 1-120 tons of suspended equal pressure air supply reciprocating grates; layered combustion coal bunkers and other boiler supporting products.

-

Small scale chain grates

-

Small Flake Type Chain Grate

-

Small scale grate

-

Small scale chain grate

Reciprocating grate

-

Small-scale chain grate stoker

-

Small Flake Type Chain Grate

Chain belt chain grate

-

Chain grate stoker

-

Chain grate stoker

-

Chain grate stoker

-

Chain grate stoker

-

Chain belt grate

-

Chain belt grate

-

Chain belt grate

-

Chain belt grate

-

Chain belt grate

-

Chain belt grate

-

Chain grate stoker

The main products produced by Yongning Grate include 10-160 tons of equal pressure air supply beam grates; 10-65 tons of equal pressure air supply large scale chain grates; 2-40 tons of equal pressure air supply small scale chain grates; 1-20 tons of equal pressure air supply lightweight chain belt grates; 1-120 tons of suspended equal pressure air supply reciprocating grates; layered combustion coal bunkers and other boiler supporting products.

-

10-ton chain belt grate

-

Yongning chain grate furnace

The Yongning chain grate is a type of mechanized combustion equipment that is widely used in industrial boilers, with a certain adaptability to coal types. The combustion method of the chain grate is moving bed combustion, and the ignition condition for the fuel is "limited ignition." The fuel enters the grate through the coal hopper, and as the chain grate moves in, the combustion process begins inside the furnace, with the burnt coal ash being discharged to the slag well at the rear of the grate. Therefore, compared to reciprocating furnaces, vibrating furnaces, and bubbling furnaces, the chain grate has higher requirements for coal quality. The mechanical coal throwing furnace essentially belongs to an unlimited ignition layer combustion grate, which has a relatively wide adaptability to coal quality.

-

Yongning chain grate furnace 15 tons

The Yongning chain grate is a type of mechanized combustion equipment that is widely used in industrial boilers, with a certain adaptability to coal types. The combustion method of the chain grate is moving bed combustion, and the ignition condition for the fuel is "limited ignition." The fuel enters the grate through the coal hopper, and as the chain grate moves in, the combustion process begins inside the furnace, with the burnt coal ash being discharged to the slag well at the rear of the grate. Therefore, compared to reciprocating furnaces, vibrating furnaces, and bubbling furnaces, the chain grate has higher requirements for coal quality. The mechanical coal throwing furnace essentially belongs to an unlimited ignition layer combustion grate, which has a relatively wide adaptability to coal quality.

-

Yongning 6-ton chain belt grate

Yongning Grate

-

10-ton chain belt grate

-

Chain grate stoker

-

Chain grate stoker

-

Chain grate stoker

-

Chain grate stoker

Hydraulic grate

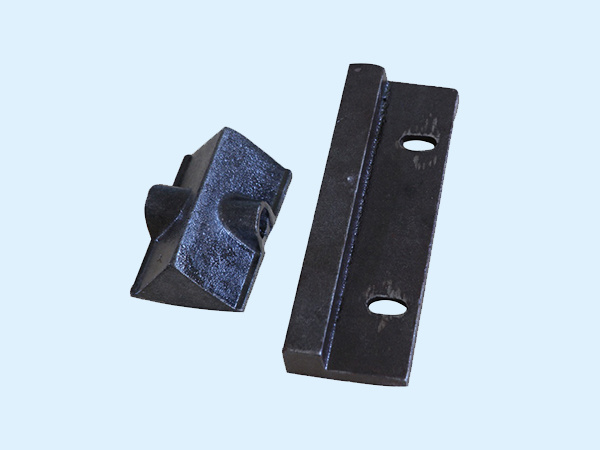

Grate accessories

-

Reciprocating grate accessories

-

Combustion Grate Spare Parts

-

Reciprocating grate accessories

-

Grate Parts Manufacturer

-

Reciprocating grate accessories

-

Reciprocating grate accessories

-

Reciprocating grate accessories

-

Reciprocating grate accessories

-

Reciprocating grate accessories

-

Scale grate accessories

-

Grate Parts

-

Scale grate accessories

-

China Grate Parts Manufacturer

-

Stoker Components

-

Scale grate accessories

-

Grate Spare Parts Producer

-

Grate Spares Factory in China

-

Reciprocating grate accessories

-

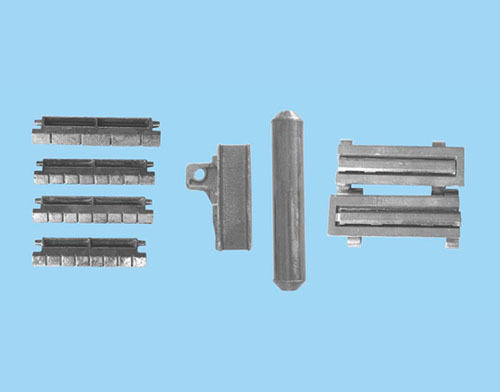

Beam grate accessories

-

Chinese Stoker Components Supplier

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Beam grate accessories

-

Grate accessories

-

Chain grate stoker accessories

-

Beam-type grate accessories

-

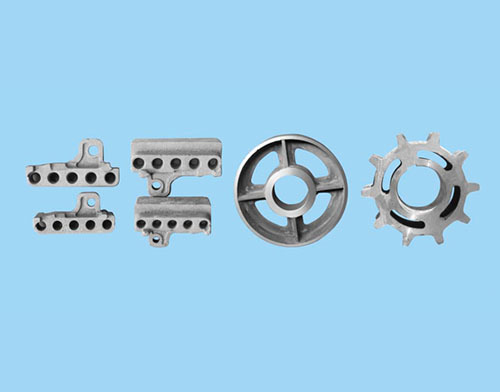

Reciprocating grate accessories

-

Scale-type grate accessories

-

Scale-type grate accessories

-

Disappearing large tooth wheel

-

Small scale clamp board

-

Small scale furnace bar